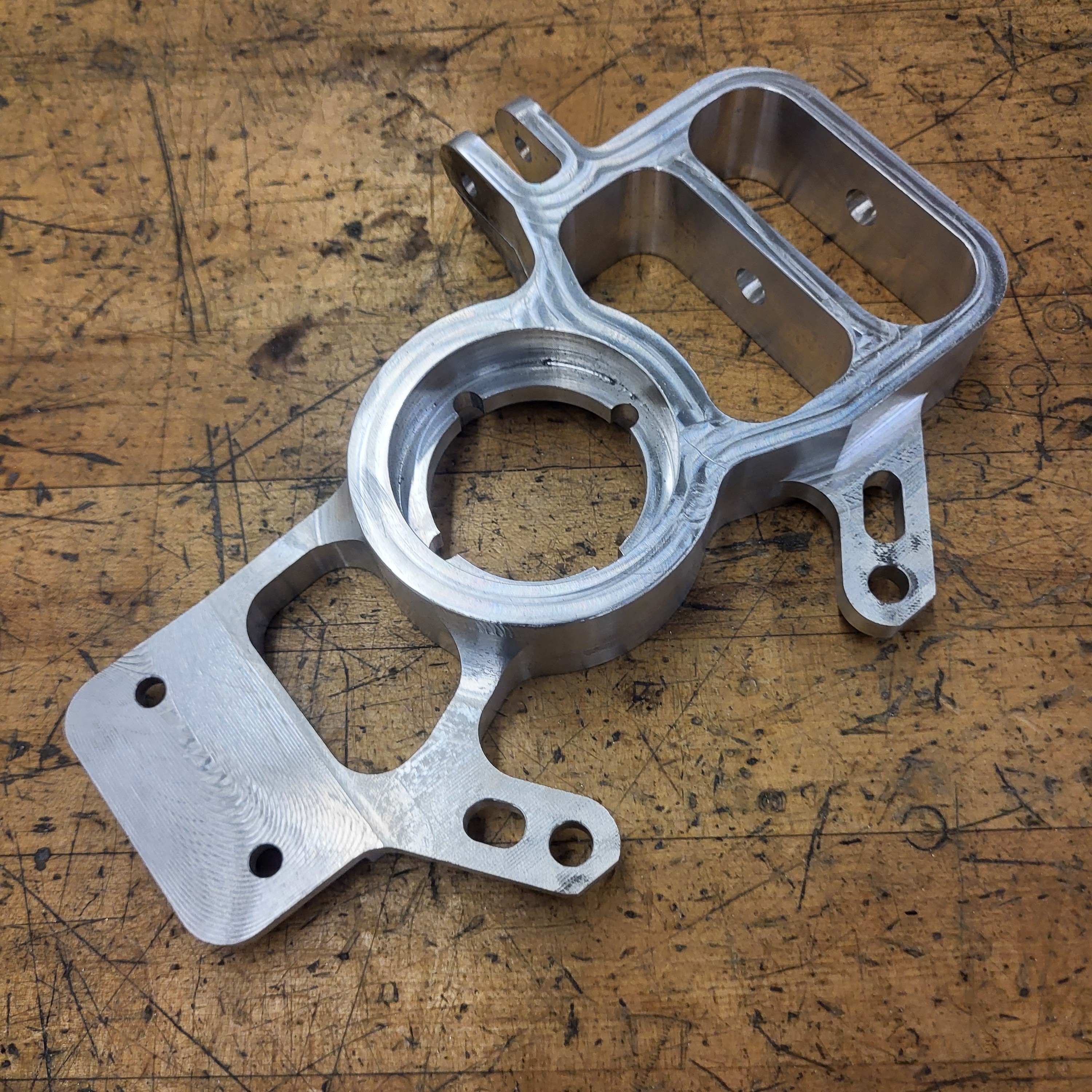

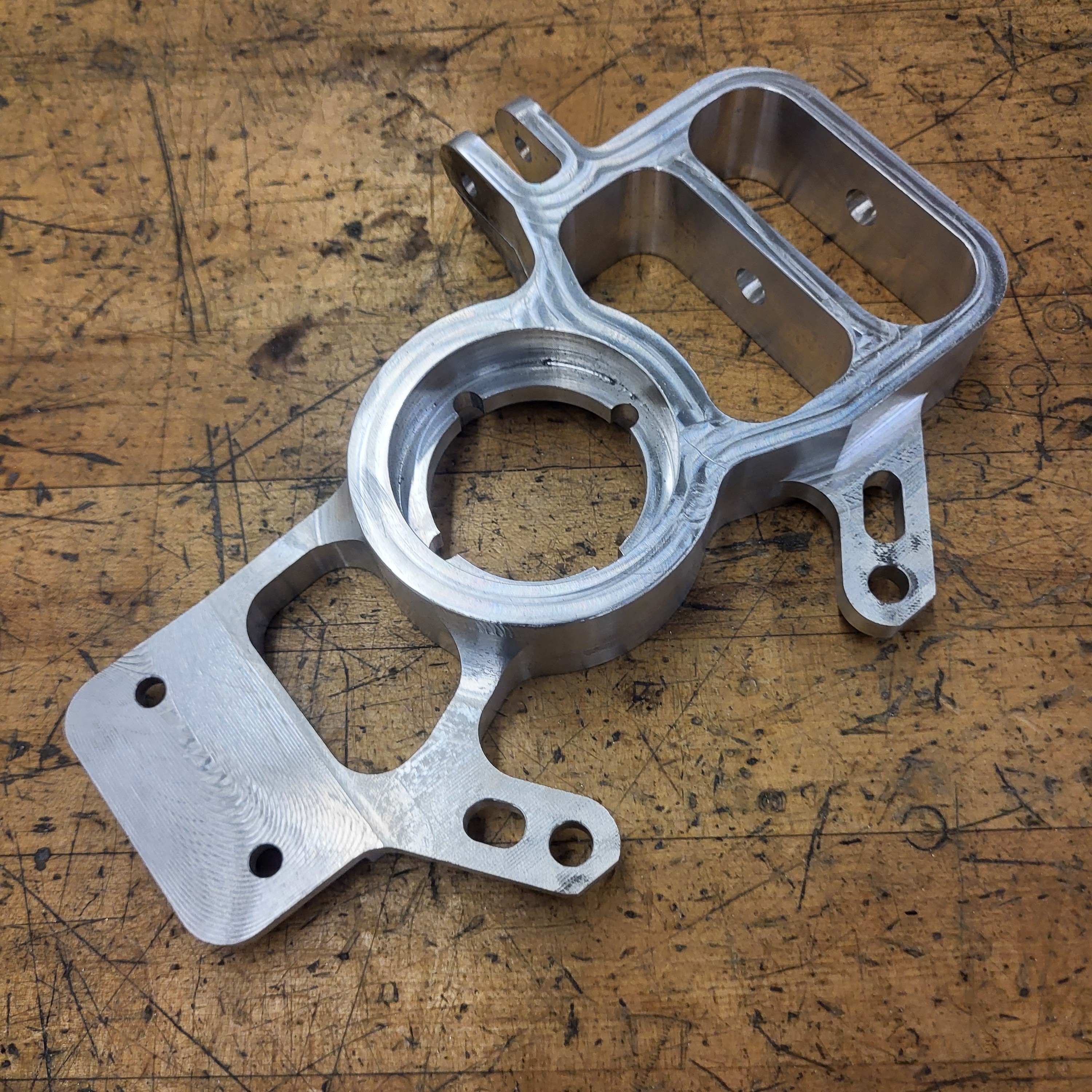

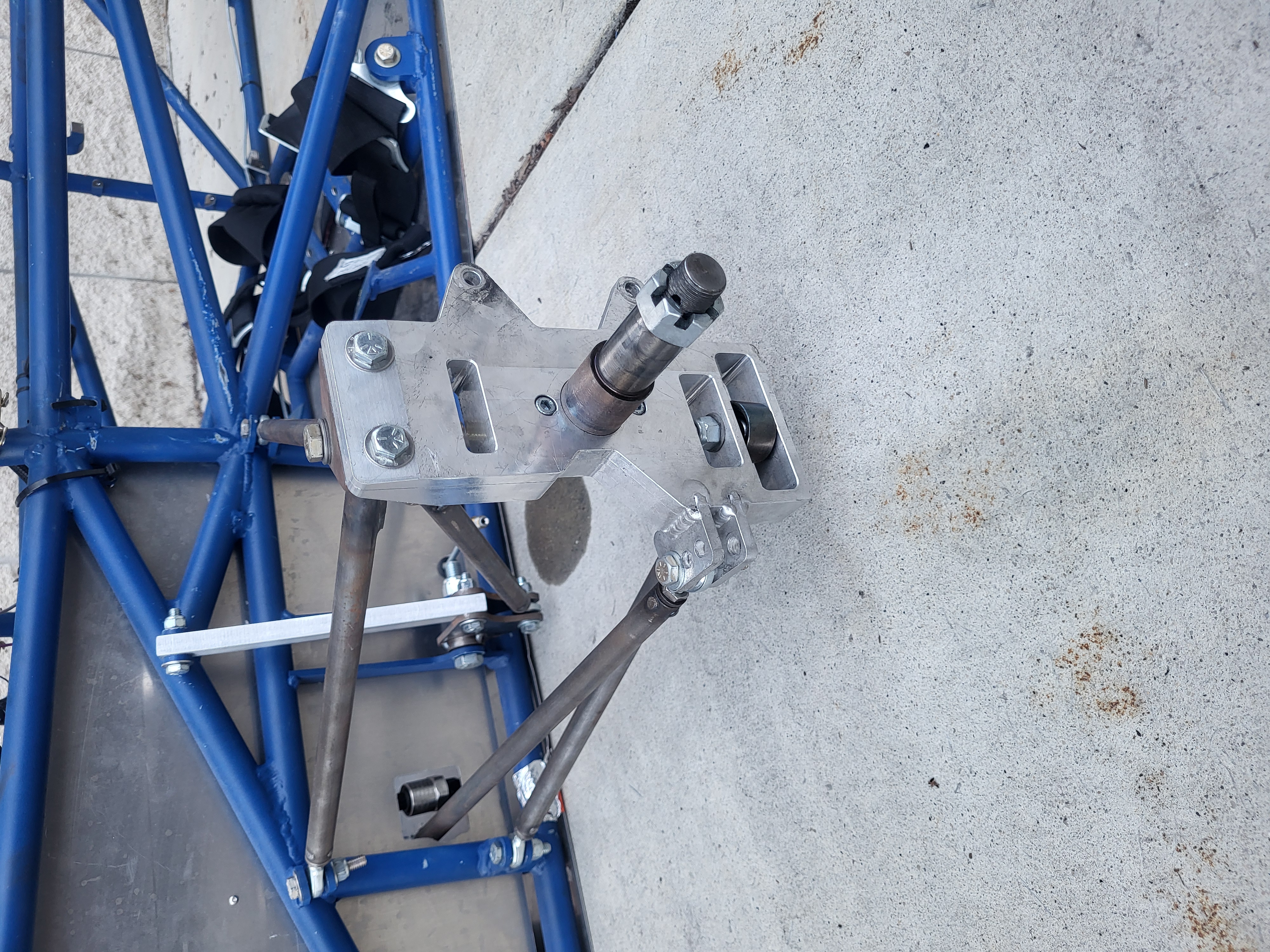

Finished Upright

This was the finished component. This was year two, revision one (in the end, we made a second pair of uprights that year).

For two years in a row the Formula team had me machine their front uprights. These were apart of the suspension assembly and held the tapered roller bearings for the front wheels. The first year, the parts were much simpler in shape, and due to my lack of experience at the time, we machined the parts in five 3-axis setups each. The second year I had more experience on the machines and we made the parts on our 4th axis in a single setup each.

This was the finished component. This was year two, revision one (in the end, we made a second pair of uprights that year).

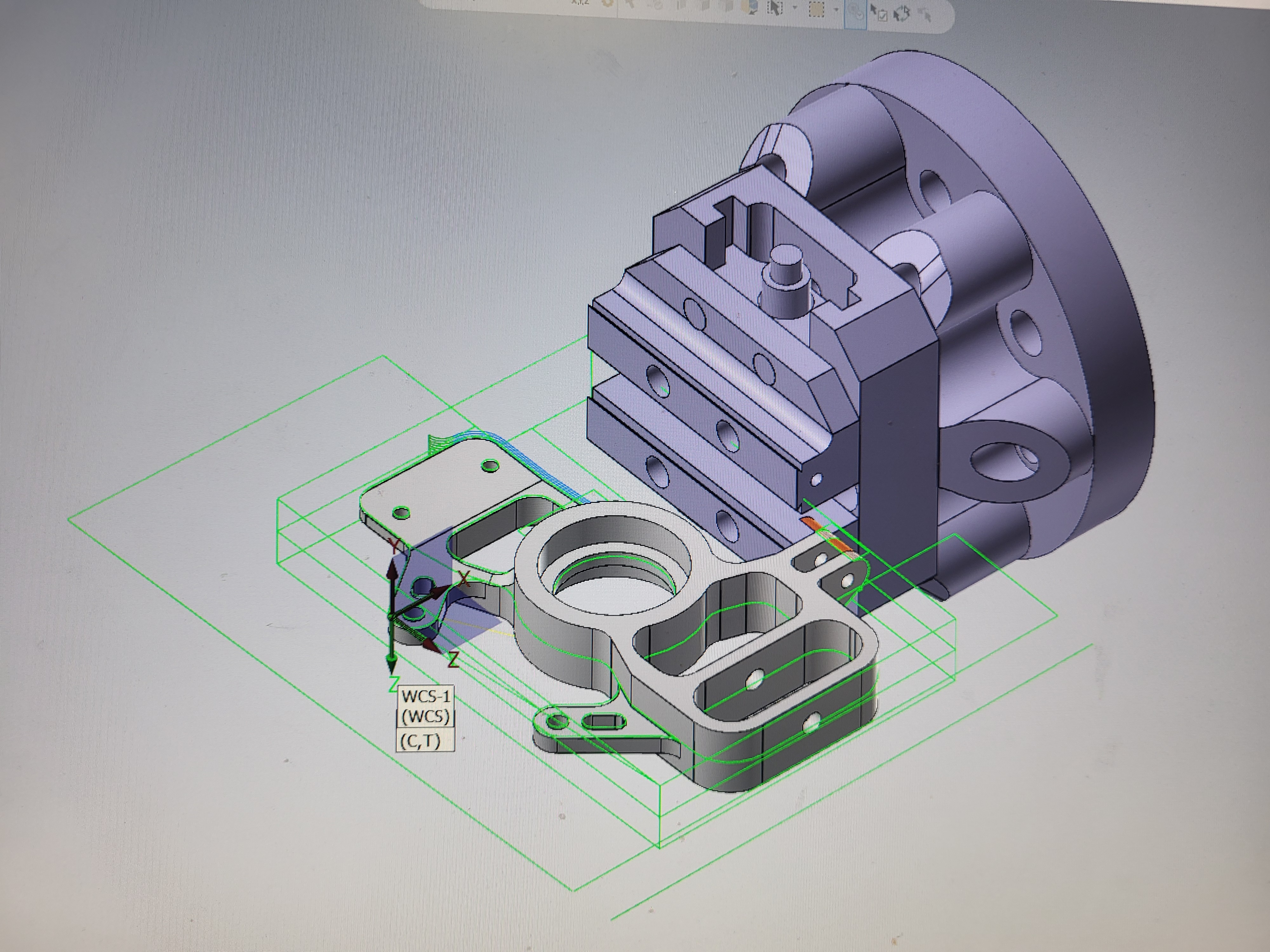

The second year I was able to machine each upright is a single setup and leave a thin tab so the part broke off as a completed part.

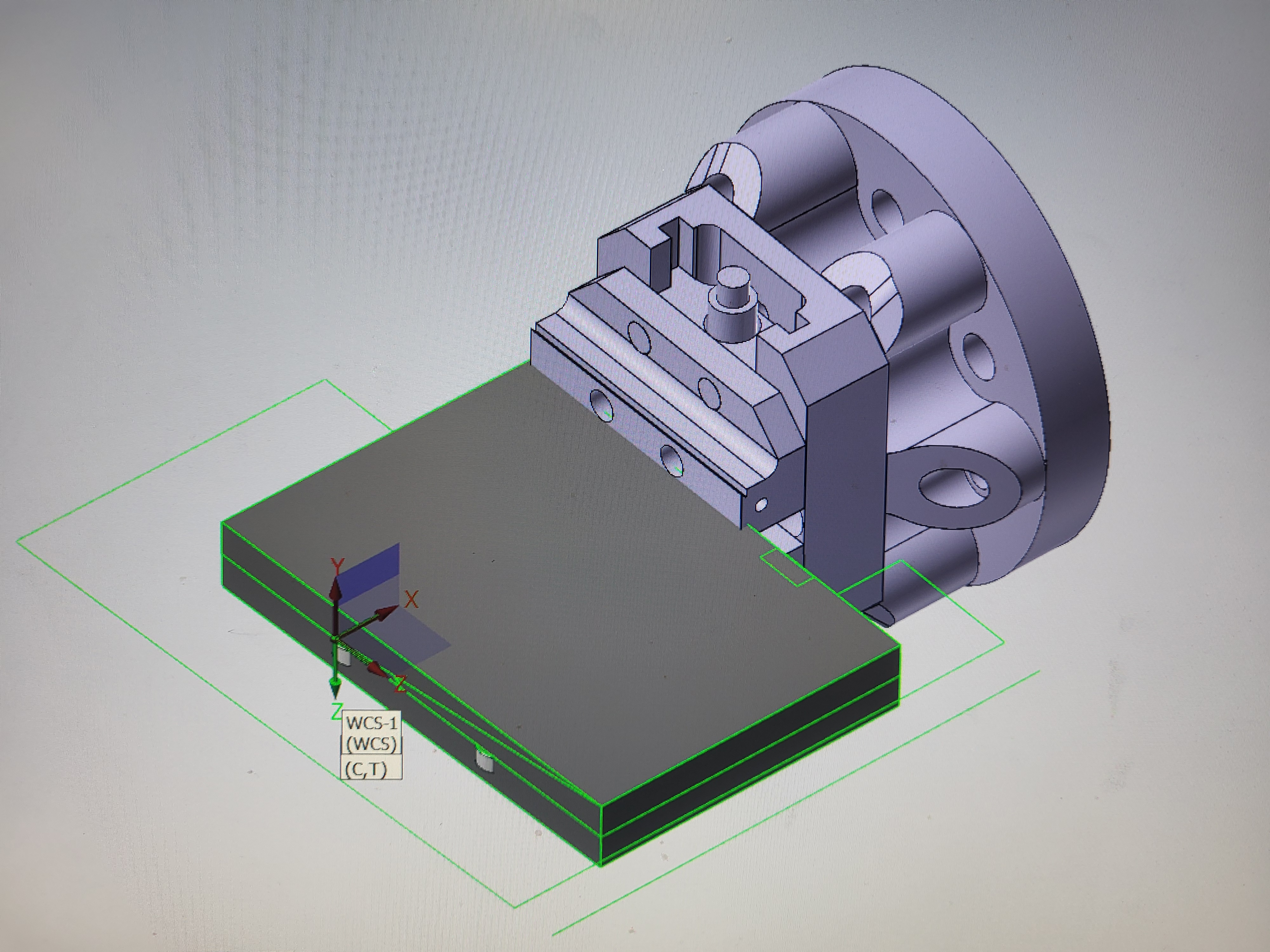

This is how I setup the initial stock in Mastercam and on the machine.

And here is how the part was setup in Mastercam.

As I mentioned before, I was less experienced the first year and I did all this work in 3 axis setups. This was after the first one.

Here are the finished uprights from the first year. They were a little blockier than year two.

This shows the year-one uprights installed on the car. As you can see from the picture the upright is a critical component of the suspension assembly.

Thankfully we all learned a lot and the second-year uprights turned out lighter, better designed, and better machined.

I am best contacted via text or email.