Formula Electric

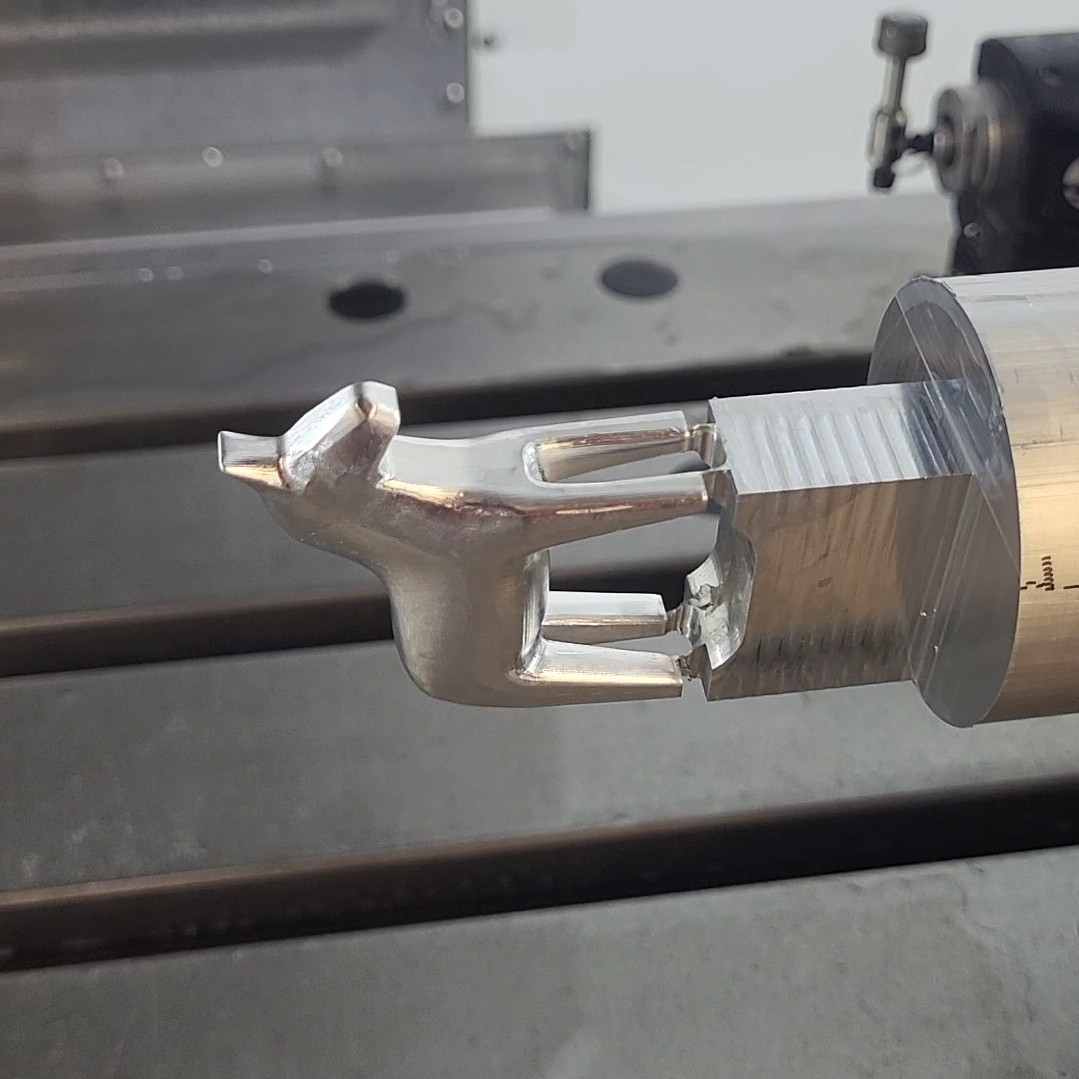

This was one of the front uprights for BYU's Formula car. Its role on the car was to attach the suspension to the wheel.

This is a selection of some of the many projects that I have worked on or have been connected to. Many of these projects happened while I worked at the Brigham Young University Prototyping Lab. We were a machine shop set up to help university engineering competition teams and research groups. Some of the notable groups I helped, were the Formula Electric team, Compliant Mechanisms Research Lab, SAE Baja Offroading team, and several research projects funded by NASA.

This was one of the front uprights for BYU's Formula car. Its role on the car was to attach the suspension to the wheel.

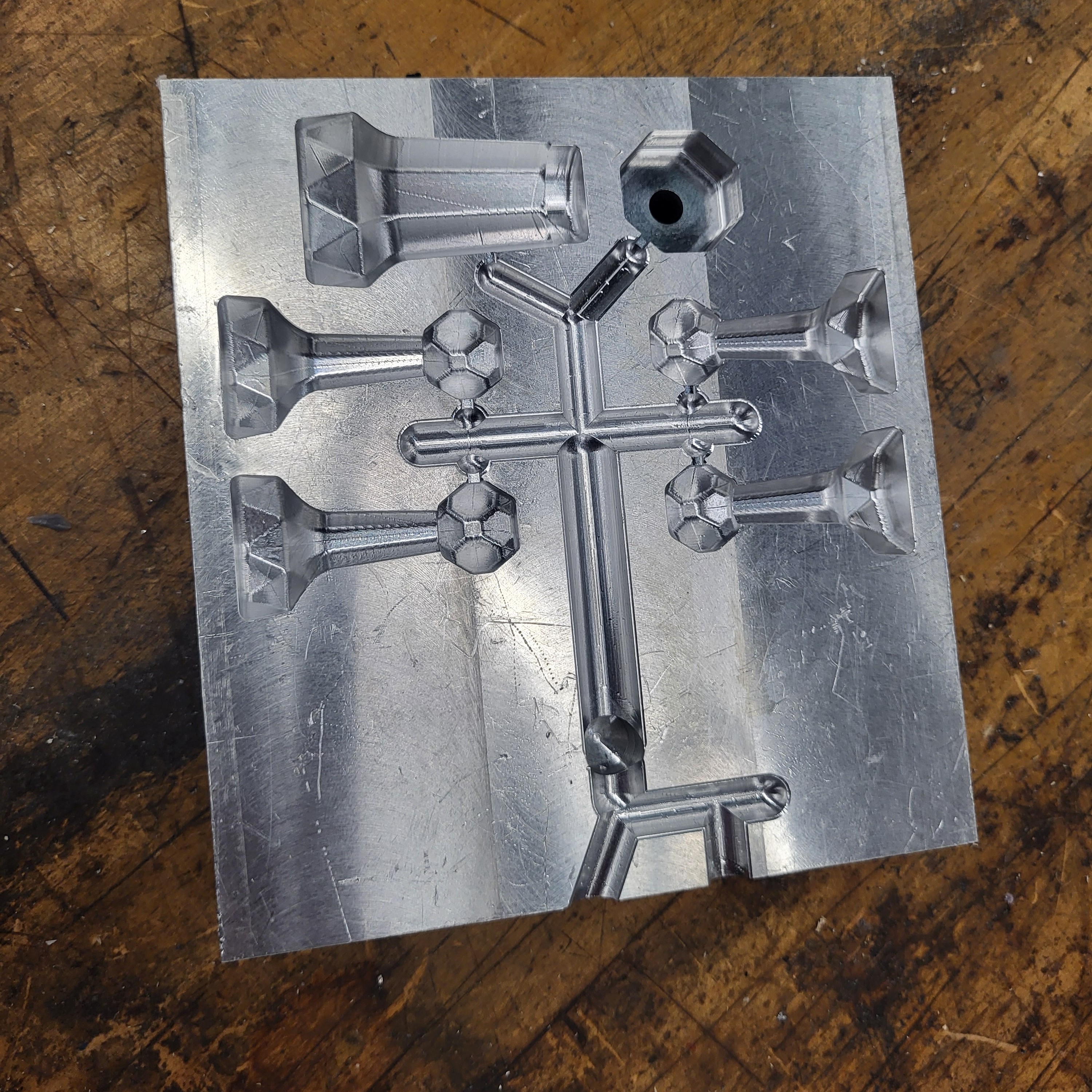

This was just a personal project of a student. He designed this injection mold and asked me to help him machine it.

The BYU Prototyping Lab often had all sorts of odd projects. I modeled and machined these clamps to assist in holding material while it was machined.

I have Swedish heritage and I machined this for my daughter for Christmas on the 4-axis CNC mill that we had.

This was the power transmission out shaft for the SAE BYU Baja offroading vehicle. It was machined completely on our CNC Mill Turn.

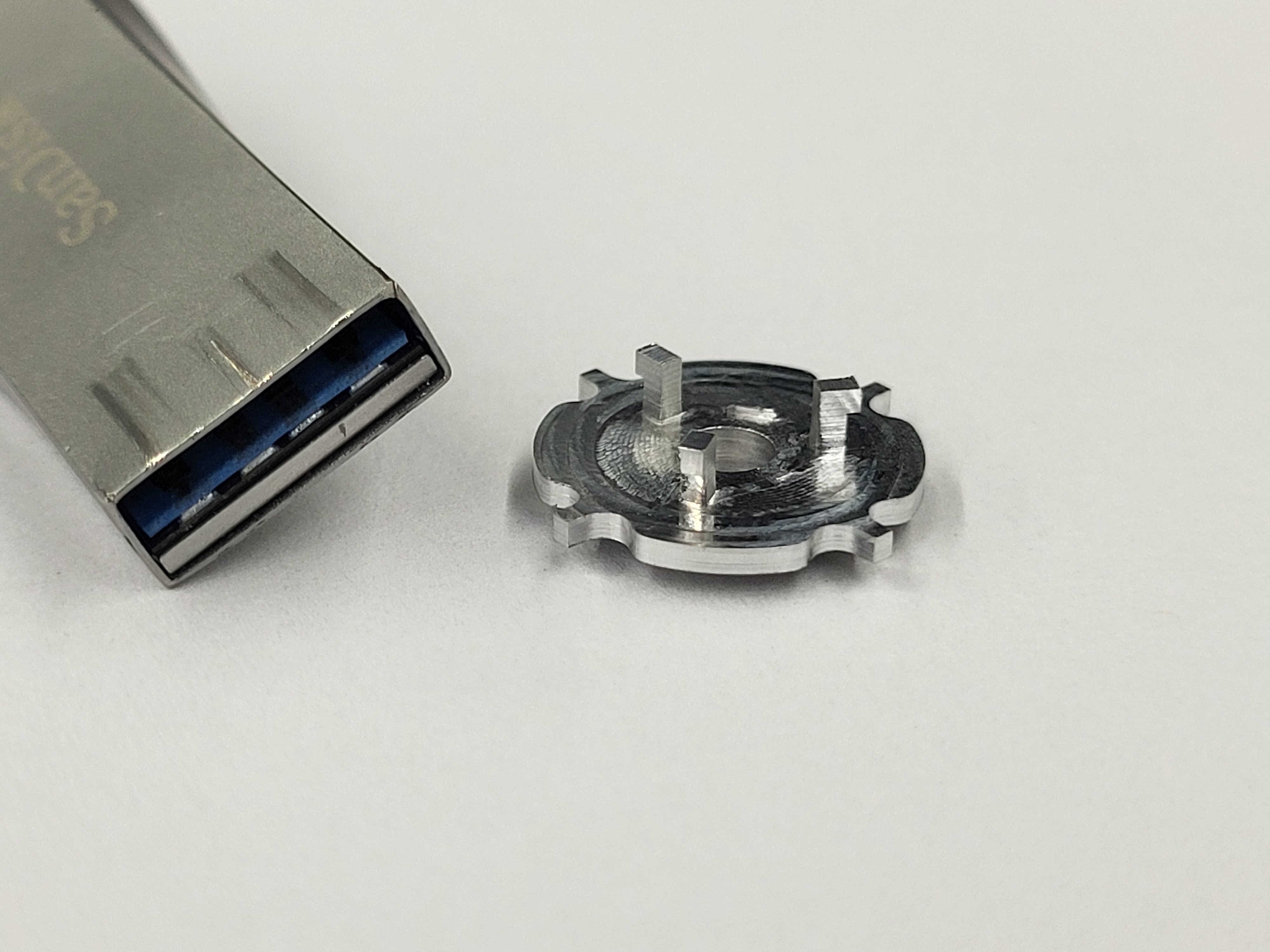

One of my favorite parts of working at the BYU Prototyping Lab was the wide range of projects we got from big to small. This was a custom washer that a team needed to retain some springs.

There was one student who was researching coating propellers and how that changed the fluid mechanics. He needed several small propeller with varying geometry and I helped machine those parts for him.

This ring was machined from 321 stainless steel. It is a titanium stabilized stainless and is a high temperature alloy. This ring when rotated by a servo will adjust the fins by splaying them out or pulling them tight together.

This is part of a personal project where I engraved a stainless steel box with a 0.03" ball endmill. I programmed tha machine to use that same tool and stipple the background of the engraving. It left a stunning texture.

This was another rocket part I machined for the rocketry club this time. This was an injector plate made from stainless with 1.3 mm holes.

Machined from aluminum, this part I modeled and machined to simply look good. It holds the model radial engine that I machined and built while working at the BYU Prototyping Lab.

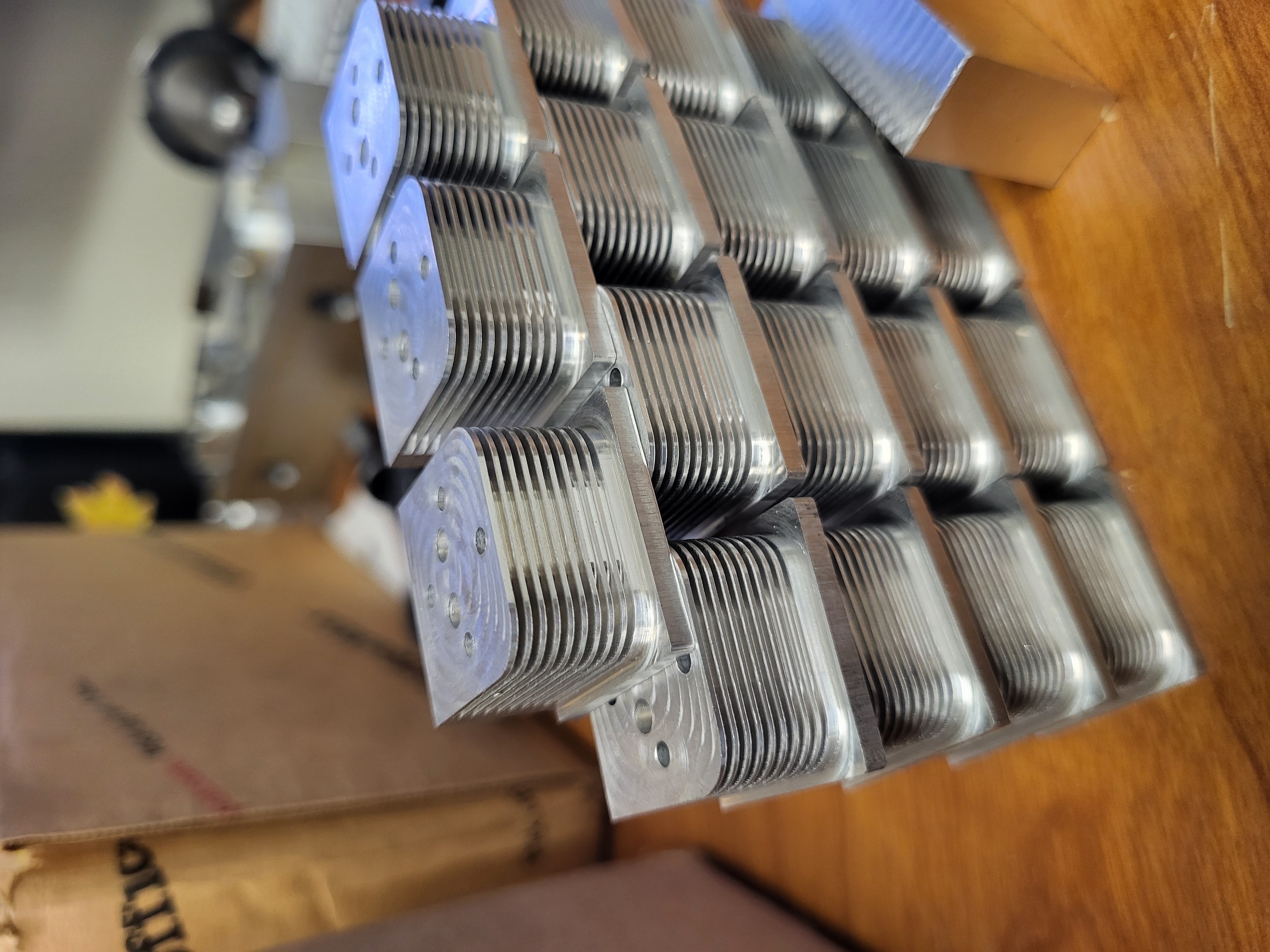

A collection of the cylinder heads for the radial engine I made.

These are a collection of the most difficults part I made while working at the Prototyping Lab. Each propeller is made up of 3 blades, 1 nose cone, 2 hub pieces (front and back), and a custom collet.

I designed and machined this screwdriver entirely on manual machines. It was purely for fun and a bit to test myself.

These were two parts I machined from Haynes 230 which is a nickel based superalloy that also has about 15% tungsten. These parts may look simple, but they were not easy and definitely had some learning moments.

I am best contacted via text or email.